- info@agrolytix.com

- +49 9131 8529452

Microencapsulation

By means of the microencapsulation, gaseous, liquid, or solid agents can be embedded in a carrier matrix or in a shell material, by which new products with customized characteristics can be produced. The most important applications of the microencapsulation include:

- The adjustment of a controlled, often delayed release of the agents out of the capsules into the environment (Controlled Release, Slow Release)

- Protection of sensitive agents from dangerous environmental influences such as sun light, oxidation, acids and bases

- Development of new product characteristics, for example by transformation of gaseous and liquid agents into free-flowing powders

- Adsorption of slightly volatile chemicals (e.g. pheromones) to a solid carrier material

- Improvement of storage stability of sensitive agents

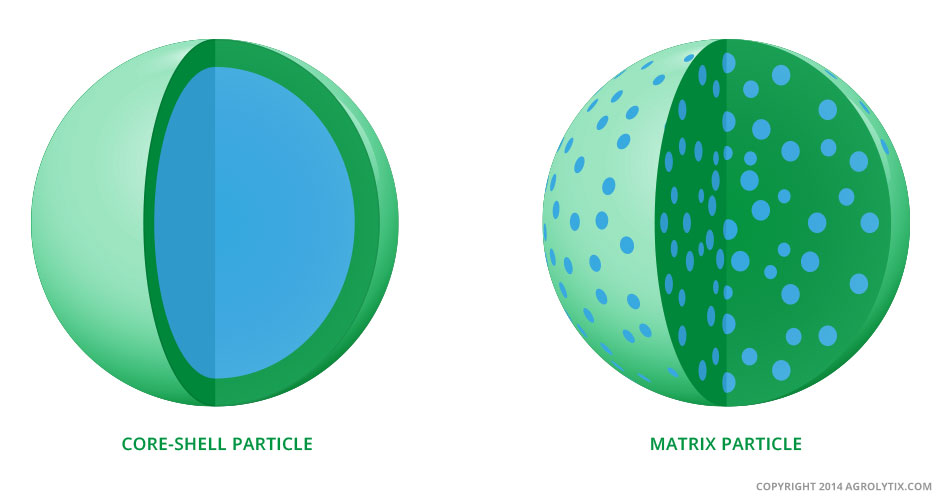

Due to the multiple areas of application of the microencapsulation, many different types of capsules exist nowadays, which can be reduced to two basic structures, however.

The core/shell particles are „real” capsules with a clear distinction between the internal core zone containing the agent and the surrounding shell. This type of capsule is especially preferred, when an instant release of the agent is desired, following a certain period of time during which the shell is degraded.

Matrix particles, on the other hand, consist of a homogeneous distribution of carrier materials and agent(s). Spherical particles in micrometer scale are often termed as microspheres. Due to their homogeneous distribution inside the microspheres, the agents reach the sphere surface and are consequently released at different times, which results in diverging release profiles. The agents’ release kinetics can be specifically changed and adjusted according to customer requirements or environmental conditions through the choice of the carrier material as well as the addition of additives to the matrix particles.